Assembly Simulation

with Virtual Reality

Project Overview

Abstract

Business process re-engineering is becoming a main focus in

today's efforts to overcome problems and deficits in the automotive and

aerospace industries (e.g., integration in international markets,

product complexity, increasing number of product variants, reduction in product

development time and cost).

With this project we apply virtual reality (VR) for virtual

prototyping (VP) to verify assembly and maintenance processes.

Partners

BMW AG, Munich, Germany.

Duration

summer 1996 - summer 1998

Movies

Functionality

This section presents some of the features present in the current

system.

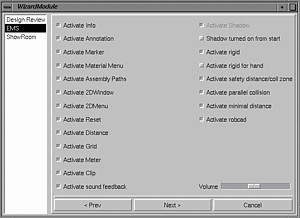

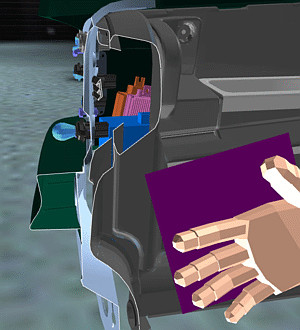

Multi-modal user interface

Multi-modal user interface

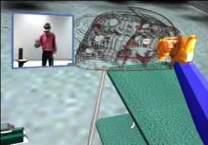

The user interacts with the VR system via several input channels: position tracking

(of his head, hand, etc.), gloves with gesture recognition (mainly used for grabbing),

voice input, and menues.

The system can use any type of display: monitor, stereo-projection, HMD,

and Cave.

In our experience, glove and HMD is best for this type of application.

Transformations

Functions in this section involve the motion of objects. The object's motion is

coupled directly to the user input, possibly with an additional constraint.

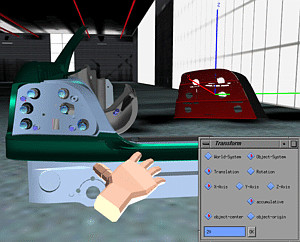

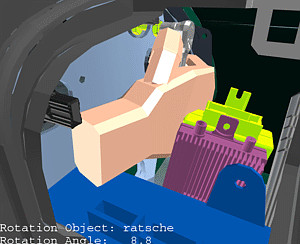

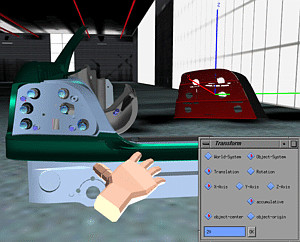

Transform

Transform

Objects can be transformed precisely by a simple 2D user-interface, by speech

input (the user says translate along x by ten). The user can choose between

the global car coordinate frame or the object's local coordinate frame.

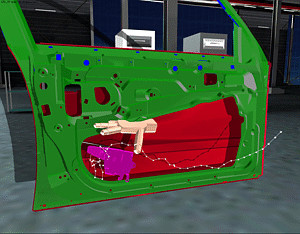

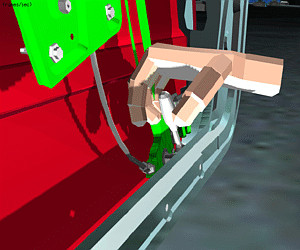

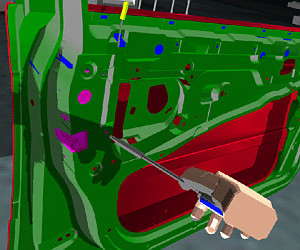

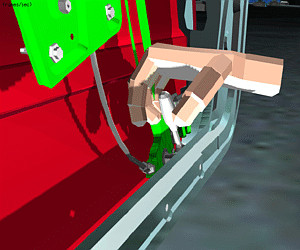

Grabbing

Grabbing

Probably the most intuitive way to move objects is to simply grab them and put

them somewhere else.

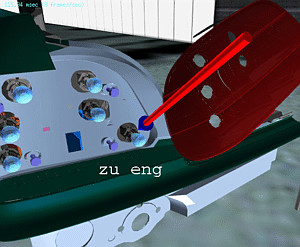

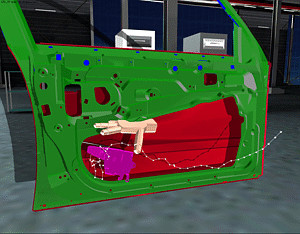

Collision prevention

In the "normal" grabbing mode, objects can penetrate other parts

(with highlighting of those).

Sometimes, one wants to move objects by grabbing them and still disallow

penetrations. The system provides for gliding of objects. In that

mode, objects being grabbed will not penetrate other parts; instead, they

will "glide" along the surface and try to follow the hand as much

as possible.

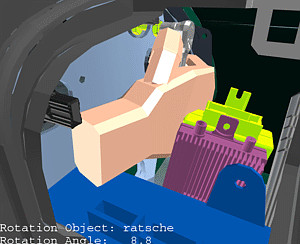

Restricted transformation

The motion of objects can be restricted when moved by the user's hand.

In this case, objects are not fixed rigidly to the user's hand; instead

they follow its motion, but only along one of the three coordinate axes

(local or global).

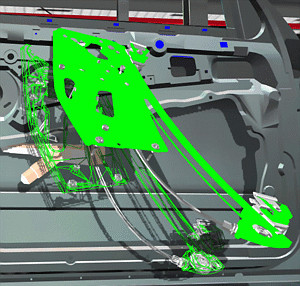

Assembly paths

Assembly paths

During the motion of a part, its path can be recorded as an "assembly path".

Such paths can be played back, saved and loaded, edited, and many other functions

can be performed with them. They can be turned into a MPEG movie for later inclusion

in a HTML document. And they can be exported to other CAD systems.

Geometric Analyses

These are functions which help the user to analyze the geometric situation.

Typical actions involve collision detection, distance computations, etc.

Clipping plane

Clipping plane

The user can examine the geometry more closely and more conveniently by a clipping

plane. When switched on, all geometry is clipped by that plane in real-time as

the user moves it through space. The motion of the plane can be resstricted like

other objects. The result of a clip operation can be highlighted and saved for

export to other CAD programs.

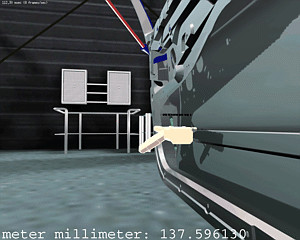

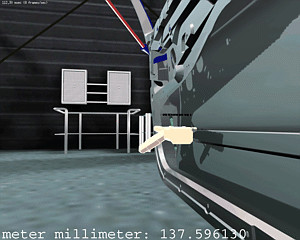

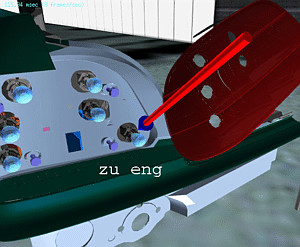

Distance

Distance

Distances between two parts can be measured interactively by two different metaphors:

the virtual yardstick and the rubber band. In both cases the VR system computes

the distance between two points on the surface of parts, and displays that as

2D text in a "heads-up" display.

Minimal distance

The VR system can compute the minimum distance between two parts.

When the computation is finished, the result is displayed in the heads-up

display.

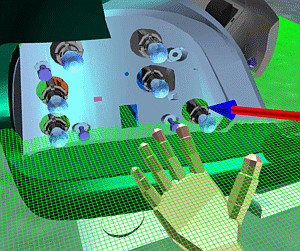

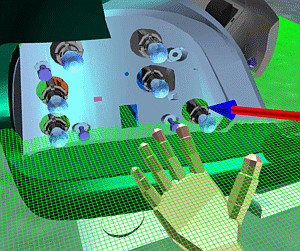

3D grids

3D grids

In order to estimate the distance 3D and 2D grids can be displayed and positioned.

They come in a variety of pre-defined measures.

Penetration depth

When a part moves along its assembly path, it might penetrate other

objects. The maximum depth of any such penetration can be computed by the

system in near-real-time.

The result is displayed.

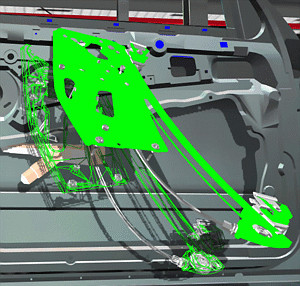

Visualization of allowed rotation

Visualization of allowed rotation

In order to find out the space a worker has to handle a wrench or other tool,

the system can display the collision-free amount of rotation.

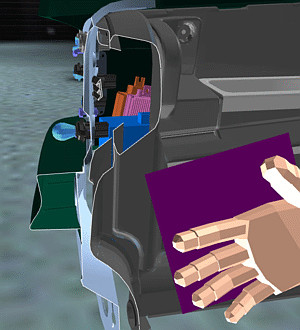

Inverse kinematics

Inverse kinematics

The system can compute simple inverse kinematics. This allows for "door-like"

mechanisms which can be manipulated by the user interactively. In addition, tools

can be made "snap" to snap on to screws and parts can snap into slots.

Whenever a tool or part is snapped in, it cannot be moved otherwise than

about the pre-defined axis of the screw/bolt/joint, resp.

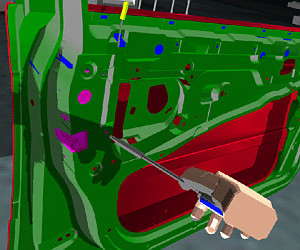

Collision detection and handling

Several features exist to help the user find out collisions, clashes, or

near-clashes.

Highlighting

Highlighting

When a part penetrates another one, it is highlighted red. When the get closer

to each other than the allowed safety distance, it will be highlighted in yellow.

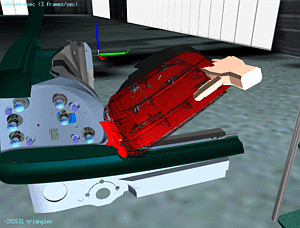

Visualizing the collision area

Visualizing the collision area

Sometimes the user wants to see more details about the area of collision. In this

case, the system can display all polygons which are penetrating polygons of some

other part.

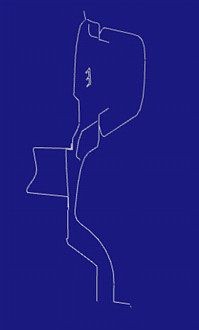

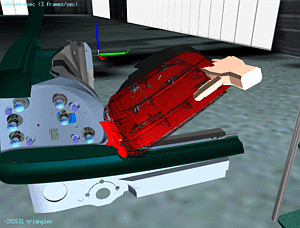

The ghost

The ghost

Another way of handling and displaying collisions is what we call the "ghost":

whenever a part penetrates another one, its solid representation will stay at

the last valid (i.e., collision-free) position. A wireframe representation (the

"ghost") will be placed by the system at the current actual position

of the colliding part.

Gliding

See Collision prevention

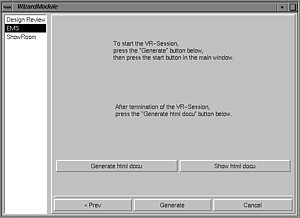

Documentation

Documentation

If a certain assembly task cannot be done, then the result of the verification

session should be a precise as well as intuitive understanding why that is.

During the VR session, the user can record certain results. At the end, the

system can compile a HTML page from the data.

Snapshot

Snapshots from the current viewpoint can be made.

Annotations

Annotations

The user can place markers (e.g., arrows) in the scene and annotate these by spoken

text. The markers and texts can be saved for inclusion in the documentation.

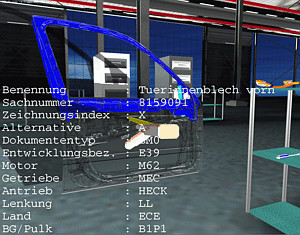

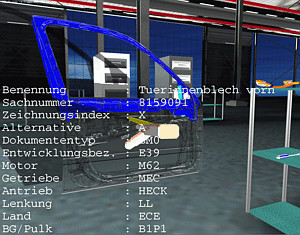

Part info

Part info

In order to verify that the currect versions of parts have been used to create

the virtual environment, the user can query all parts for their status information.

Modification of the (virtual) user representation

Functions in this section influence the way the VR system handles or

restricts some of the user's input.

Fixed height

The user can be fixed to a certain height. When navigating with

point-and-fly or spacemouse, this is practical when the user

wants to stay "on the ground", i.e., always keep the

"real" eye level.

User scale

Sometimes it can be convenient to scale the user to a different size than

what he shold really have compared to the virtual environment.

For instance, when the user wants to examine closely some details of the

geometry, his virtual representation can be scaled down.

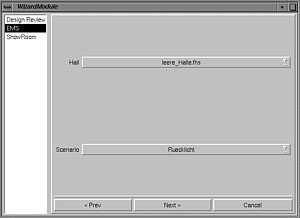

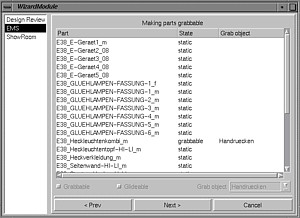

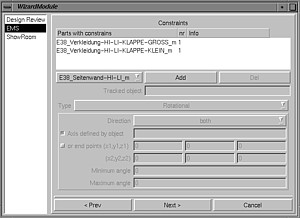

Creating a scenario

In order to create a new scenario for assembly simulation,

a high-level GUI (similar to Windows "wizards")

helps the user with configuration.

It asks the user to load the parts, tools, and other stuff,

then the user can configure certain behavior like, joints, physically-based

simulation, snapping, etc.

A lot of "standard" functionality does not need to be configured.

Other application areas, such as design review, and styling review,

have similar Wizards to help the user create scenarios in that application

domain.

More projects

Gabriel Zachmann

Last modified:

Sat Sep 10 16:01:26 MDT 2005

Multi-modal user interface

Multi-modal user interface Transform

Transform Grabbing

Grabbing  Assembly paths

Assembly paths

Clipping plane

Clipping plane Distance

Distance 3D grids

3D grids Visualization of allowed rotation

Visualization of allowed rotation Inverse kinematics

Inverse kinematics Highlighting

Highlighting Visualizing the collision area

Visualizing the collision area The ghost

The ghost Documentation

Documentation Annotations

Annotations Part info

Part info